Within the industrial cooling domain, refrigerant play an essential role in guaranteeing a proper system response. However, in the last years, their environmental impact has been widely debated, as it has been of great concern; therefore, the industry has put their efforts into evolving and creating greener alternatives by trying to find the right balance for efficiency, performance and environmental safety.

The history of refrigerants has been focused on a constant search for more efficient and safer options. In the past, substances were commonly used, such as ammonia (R-717) and chlorofluorocarbons (CFCs), which could considerably damage the ozone layer.

Even though introducing hydrofluorocarbons (HFCs) to replace CFCs was a bechmark for significant improvement, as they do not damage the ozone layer, HFCs possess high levels of Global Warming Potential (GWP), which makes them one of the main drivers of climate change.

In response to these concerns, new generation of low-GWP refrigerants have been developed, such as hydrofluoroolefins (HFOs), as well as mixes of HFOs and HFCs. Furthermore, the use of natural refrigerants like ammonia, CArbon dioxide (R-722 ) and hydrocarbons, is being reassessed, as they have a lower environmental impact.

The invironmental impact of refrigerants.

These are the two main factors for the environmental impact of refrigerants:

- Global Warming Potential (GWP): Term used to describe the capacity of a gas to remain active in the atmosphere. High-GWP refrigerants promote global warming.

- Ozone Depletion Potential (ODP): Term used to describe the capacity of a gas to destroy the ozone layer, which protects us from damaging sun UVradiation. Refrigerants depleting the ozone layer, such as CFCs, are banned or in the process of being removed from the market.

Choosing the right refrigerant: a crucial factor of sustainability

- Efficiency: The capacity of a refrigerant to efficiently absorb and release heat.

- Performance: The capacity of a system to reach and maintain the desired temperature.

- Enviroment impact: The GWP and ODP levels of a refrigerant, as well as their leak potential

- Safety: Flammability, toxicity and other risks associated with refrigerants

- Regulations: Local, national and international guidelines tha regulate the use of refrigerants.

-1.jpg?width=758&height=448&name=Portadas%20de%20blog%20(1)-1.jpg)

Green refrigerants: sustainable options for the futute.

The refrigerantion industry has increasingly been adopting greener refrigerants with lower levels of GWP and ODP. Some of the most promising options are:

- Hydrofluoroolefins (HFOs): They offer low levels of GWP and do not damage the ozone layer; however, some HFOs can be slightly flammable. HFOs are commonly used in different aapplications for HVAC and Refrigeration systems, from food refrigeration to building acclimatization.

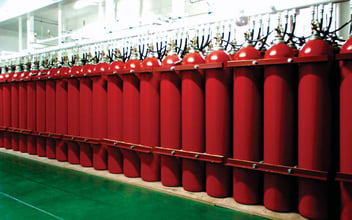

- Natural refrigerants: While ammonia, carbon dioxide and hydrocarbons provide natural options for low-GWP and ODP refrigerants, they need to be used with additional safety precautions, due to their flammability and toxicity. Ammonia, for example, is used for industrial cooling and is known for being efficient and enviromentally-friendly. On the other hand, carbon dioxide, in the form of transcritical CO2, is used as a common alternative in comercial refrigeration.

Conclusion

Choosing green refrigerants is a fundamental responsability for Engineers and contractors of the industrial cooling and commercial refrigeration industries. Knowing about important factors like efficiency, performance, enviromental impact, safety and regulations will set the path to making informed decisions that can contribute to a more sustainable future

Adopting innovative technologies and promoting collaboration among the industry, th goverment and environmental organizations are key to achieving a worls where refrigerations is efficient, safe and environmentally- friendly.

Froztec International is a authorized distributor of CO2/ ammonia equipment for Latin America. Cantact us to help you select the best refrigeration equipment option to meet your needs.

Some of our brands:

An honest and accurante assenssment of your specific needs is key to consolidating a project in needd of maximum efficiency.

Related

Discover more related articles

Categories of natural refrigerants: Which ones to use in your industry

Sustainability efforts at national and international levels are currently focused on finding substitutes that comply with environmental regulations;...

Read more »

Ammonia as a refrigerant: an alternative in your natural refrigeration...

Refrigeration systems with natural gases will set the pace for many industries, improving not only energy efficiency but generating a greater...

Read more »