All present challenges a company faces when installing industrial refrigeration systems revolve around an ever-increasing technological connectivity, energy saving and environmental concerns.

The refrigeration industry must deliver efficient projects guaranteeing the best value for the investment.

Every installation of a refrigeration system must take into account the latest innovations to secure competitiveness.

In order to maintain top performance, everyone involved in the process is responsible for safeguarding four basic premises: Specialized maintenance, supervision, problem prevention and training.

There are many kinds of challenges regarding technological advancements and their application:

1st Challenge - Breaking down all that entails an industrial refrigeration system to the final user

When technology changes, new processes are applied, and new equipment is developed. Thus, it comes as no surprise the price of a product might increase, given that they are developed with their utility and durability in mind.

Groundbreaking companies, such as Alfa Laval with their heat exchanger technology, Krack with their high technical investment in condensers, or Copeland with their energy saving compressors, are great examples of this innovation wave.

As leaders of a refrigeration project, it is mandatory to brief the final client on the technical solutions and their implications in terms of quality, maintenance cost reduction, energy or coolant savings and long term repairs, all of which increase the optimal function of the system.

2nd Challenge- Establishing key measuring and control needs for operating the system

During the process of installing refrigeration systems, defining the key information signs needed to know the optimal functioning of the system is of great importance.

Some of the basic elements to be defined are:

- Temperature, humidity and pressure sensors.

- Efficient controllers for the final user: modem equipment (for the system and programmable controllers), programming tools, interfaces, remote screens, connections, etc.

Refrigeration systems need parametric controllers, intuitive interfaces and innovative designs.

Froztec advice is: Among the available range of the market, choose equipment with smart algorithms focused on power saving. Nowadays, there are dedicated features, such as the fan speed controller and temperature, humidity and pressure regulators.

3rd Challenge - Explaining how remote technical support works to the final user

Nowadays, industries have the chance of hiring remote supervision teams allowing the refrigeration specialist to give engineering assistance by controlling the system from anywhere when faced with any problems or malfunctioning; for instance, problems with the fan, condenser or any other part or equipment, even if they are from a different industry.

In order to remotely fix such problems or to implement security measures to avoid losses, the person in charge of the refrigeration system should:

- Detect the problem.

- Control the equipment.

- Give indications to the system operator.

- Determine if it is necessary for a specialist to attend the facilities of the plant, commercial chain, factory, etc.

Presently, these tools are available, but many contractors find it difficult to implement them due to the final users lack of awareness on the advantages this technology entails.

Froztec advice is: Contact an expert in refrigeration engineering that can help you evaluate the problem and decide if it’s necessary to take certain remote actions in order to face any given problem.

Undoubtedly, the systems of remote supervision represent an extra guarantee from the refrigeration team in these times of connectivity.![]()

4th Challenge - Overcome common mistakes on the operation of industrial refrigeration systems

A specialist in refrigeration cannot make mistakes. The industry requires specialized personnel with extensive knowledge of every single one of the technological requirements of a project:

- Installation must be done under strict technical parameters according to the equipment being used to set a system.

- The manufacturer’s specifications offer exact parameters of any requirements, installation features, potential, etc.

Nonetheless, the person in charge of making decisions regarding the maintenance, supervision and usage has to take into account the key indicators to choice the best option regarding investments.

The situation is similar to buying and giving maintenance to a car in top conditions: though you may overlook small problems that don’t seem important at the moment, in the end, not making small repairs will lead to more expensive repairs in the long run, especially when installing industrial refrigeration systems.

It is challenging to create awareness on the importance of supervision, maintenance of the equipment and the usage of the right tools, even if it seems more expensive an inversion when compared to others.

In other words: every contractor should know how to transmit the importance of investing for the future to the final user.

5th challenge- Stablishing alliances with refrigeration experts and asking for training by teams up to date

Training allows you to know all these challenges while having the tools to tackle them at your disposal, so that all the personnel responsible for a project can work together.

An important part of the process is knowing the technological applications, their advantages and disadvantages and the best project and brands for such.

You can take a look at our training calendar in the following link.

Our advice is: Making alliances with engineering experts that can help your industrial refrigeration project improve their quality while saving time and money.

Nowadays, Froztec has stablished key alliances with leading brands whose innovations allow us to have successful projects by attaining our objectives in quality, saving and a larger lifespan. There are some of the above:

Leaders in basic equipment for refrigeration systems

Alfa Laval

Experts in: Separation and management of fluids.

Star product: Heat exchanger that fuses the plates together in a single metal, the acclaimed Alfa-Nova

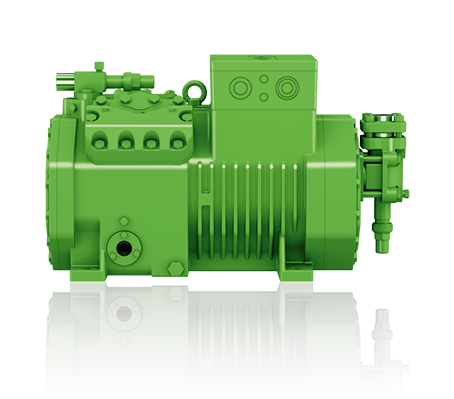

Bitzer

Experts in: Innovation and technology on refrigeration compressors.

Star product: Piston, Screw and Scroll Compressors.

Krack

Experts in: Development, manufacturing and sale of condensers, condensing units and cooling equipment for commercial level procedures.

Star product: Condensing units with micro-canal technology.

Don’t miss out on >>Refrigeration for non-engineers: How to choose a condensing unit<<

Turmoil

Experts in: Chiller technology with many applications, such as medical equipment, straight engines, etcetera.

Star product: Water or air cooling chillers.

Drake

Experts in: Versatility for the most complex refrigeration needs.

Star product: Water or air cooling chillers.

Don’t miss out on >>Water or air-cooled chiller: determining the commercial value<<

Spx Cooling Technologies

Experts in: Manufacturing condensers cooled by air and cooling towers mainly for the power generation, industries and HVAC.

Star product: Condensers cooled by air and cooling towers.

Copeland

Experts in: Resources for heating, ventilation, air conditioning and refrigeration for housing, industrial and commercial purposes.

Star product: Scroll, hermetic and semi-hermetic compressors.

Don’t miss out on >>For non-engineers: basic steps for selecting a compressor<<

Leaders in measuring accessories and controllers

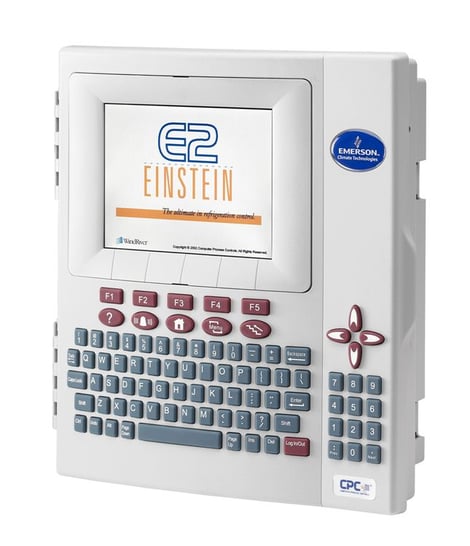

CPC Emerson

Experts in: E2 control system focused on reducing energy and maintenance of equipment.

Star product: E2 controllers.

Dixell

Experts in: Environmental protection and searching for new options for power saving.

Star product: Parametric controllers.

Hussmann

Experts in: Refrigeration systems specifically designed for food stores.

Star product: Protocol compressor units or low-profile compressor units for exteriors.

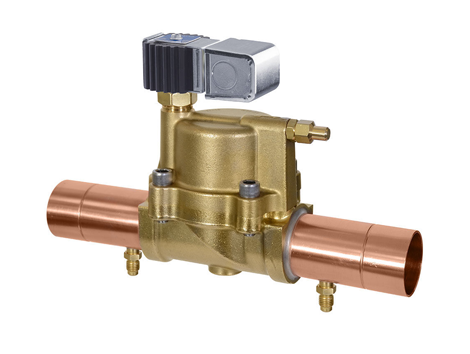

Sporlan

Experts in: Quality-focused accessories.

Star product: Pressure and filter regulation valves and oil control systems.

Froztec values greatly the alliance with all these brands, for it has been a key element for the success of our projects for installing industrial refrigeration systems.

The counseling of an expert in refrigeration is crucial for the success of a whole project, regardless of its size, complexity and challenges it faces.

When looking for a specialist in refrigeration, our advice is to focus in three key aspects: innovation, experience, and capacity for taking on the new challenges of the industry.

Related

Discover more related articles

Why choose a plate heat exchanger for your refrigeration system?

The technology behind the heat exchangers makes them an excellent alternative both in heating systems and industrial refrigeration, replacing coils...

Read more »

Basic cooling equipment for the Hospitality Industry

The hospitality industry is generating serious challenges and business opportunities for the refrigeration industry the world over. It spans through...

Read more »