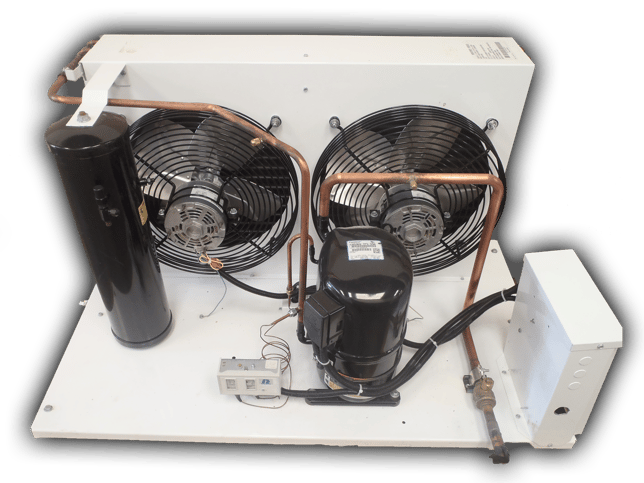

Condensing units are the most important part of a refrigeration system, since they transform the refrigerant gases into liquids to continue the refrigeration cycle and in this process, leave the latent heat in the surrounding environment.

From these, it depends that coolants are used to the maximum, optimize their life span and be profitable for a business in the long term.

Do you know which are the types of condensers? Learn more by clicking on this link.

Current challenges of the refrigeration industry

Currently, the refrigeration industry is in the process of updating environmental and regulatory demands. It faces important challenges, but some brands are taking the technological step to walk together with the changes.

The development of technology in condensing units and refrigeration systems is the answer to these challenges:

- Climate change and pollutants reduction (use of more friendly coolants for the environment).

- Increase energy savings in the face of rising prices.

- Reduce expenses and maintenance time.

- Increase the useful life of the equipment.

- Reduce the space they use and weight of the units.

- Reduce the noise they produce to improve the work environment.

- In one word, the big challenge for technology implementers in refrigeration projects is: update.

And an example of innovation that answers to these challenges is the line of condensing units developed by Krack, which rely on technological advances to keep the equipment in optimal conditions in the face of changes in the industry.

Krack condensing units, technology for the industry challenges

Thanks to the reliability, energy efficiency and overall performance of the equipment in refrigeration projects, the brand is one of the most visible leaders in the industry, covering the expectations of several industries such as: commercial refrigeration, halocarbon refrigeration, food and beverage manufacturers, air solutions manufacturers, among others.

Krack offers the most extensive selection of evaporators, condensing units, condensers, dry chillers and custom evaporators that maximize operating performance, allow efficient energy consumption and reduce the total cooling load.

Krack, condensing units with return on investment in the medium term

Although, at the beginning, the equipment of condensing units can have a higher cost compared to other brands, Krack is interested in savings and benefits for businesses in the medium and long term:

- Savings of up to 75% of refrigerants using technology such as microchannel technology.

- Increase in the useful life of the equipment under the most extreme conditions of the industry.

- Up to 40% lighter, quieter, faster and easier to install, saving time and resources.

- Savings in maintenance since it has easy access technology.

- Installed material to avoid wear with considerable cost reduction in changes and repairs.

- Savings in gasket costs thanks to its integral structure.

- Sections easy to replace with high availability of spare parts.

- Environmentally friendly products and that meet international standards.

- Efficiency in energy consumption with standard PSC motors and optional EC engines.

Krack condensing units, innovation with 75 years of experience

Each project or refrigeration system has different requirements but the Krack brand has focused on the versatility of its condensation technology.

Therefore, its condensing units offer the following:

- Interior, exterior, remote and satellite models.

- Low and medium temperature applications with a variety of coolants including R-22, R404A and R507.

- Force from 1/2 to 120 h.p. with configurations of single, double and parallel compressors.

- Variety of compressors including Ingersoll Rand, Copeland, Tecumseh, Carlyle and Bitzer.

- Specialized compressors include two-stage compressors and screw compressors.

Energy efficiency and durability is the promise that Krack has fulfilled in the challenges that the experience of great projects has brought us. Without a doubt, Krack is a key piece in the way towards a better cooling system.

If you have thought about using the Krack brand for any of your refrigeration projects, do not hesitate to consult with a specialist in systems that can guide you on the best equipment to meet your needs.

Related

Discover more related articles

Categories of natural refrigerants: Which ones to use in your industry

Sustainability efforts at national and international levels are currently focused on finding substitutes that comply with environmental regulations;...

Read more »

Ammonia as a refrigerant: an alternative in your natural refrigeration...

Refrigeration systems with natural gases will set the pace for many industries, improving not only energy efficiency but generating a greater...

Read more »