Refrigeration plays a pivotal role in the function and performance of the medical equipment you rely on to enhance and save lives. With so much on the line, your components require a specialized chiller with a superior level of consistency and reliability. Industrial medical chillers deliver more temperature accuracy and capabilities designed specifically to maximize uptime so that you can run 24/7.

This article will cover more on the right refrigeration methods to maximize component uptime, including the questions to ask before choosing the best one for your needs.

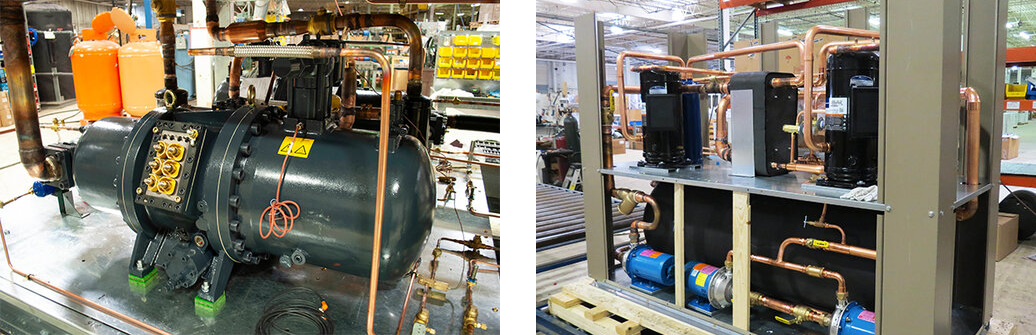

Comfort cooling chiller vs. medical chiller

When it comes to amplifying uptime, the secret is in the type of chiller you use. One of the biggest mistakes we see in the medical industry is choosing a standard comfort cooling chiller instead of an industrial-grade medical chiller. While standard comfort chillers have their place in some commercial applications, medical equipment isn’t one of them. Standard comfort coolers lack vital performance capabilities that can significantly decrease component uptime.

- Standard comfort chillers

Standard comfort chillers are not suited for cooling medical equipment. These chillers are only designed to operate for four, five, or perhaps six months when the weather is warmer. When colder months hit, many comfort coolers develop refrigeration issues that can decrease medical equipment uptime.

- Medical chillers

Conversely, medical chillers are specialized to focus on process cooling for year-round operation, making them ideal for medical components. They maintain consistent performance, whether it’s 125˚ F or -40˚ F – or any temperature in between. This expansive swing is possible, thanks to a larger condenser for warm weather and a flooded head pressure control in cold weather.

When comparing the differences between the two types of chillers, industrial medical chillers are the ideal choice for medical equipment, especially when uptime and performance are chief concerns.

Medical chiller applications

Medical equipment suitable for refrigeration in medical chillers varies widely, from imaging machines to pharmaceutical equipment. As a forward-thinking medical chiller manufacturer, we design, fabricate, and test refrigeration solutions to maximize uptime for:

- MRI machines

- CT scanners

- Linear accelerators

- Laboratory reagents and pharmaceutical equipment

- Medical cannabis and THC extraction equipment

Do you need refrigeration for medical equipment not listed here? Contact us to learn how we can help.

Questions to consider when looking for a medical chiller

To help ensure you receive the best medical chiller for your application, we help customers consider several critical factors before putting our engineering knowledge and expertise to work. When you choose us, we’ll walk you through the following questions as part of the medical chiller selection process:

- What is the Tesla rating of your component?

If you need a medical chiller for an imaging machine, knowing the strength of its magnet in Tesla units can help us design a solution specifically to meet its requirements.

- - What temperature is required?

Medical equipment requires accurate temperature control to improve uptime. We offer capacity modulation without high degrees of compressor cycling to help our recirculation system maintain a precise temperature at +/- 1°F.

- - What type of refrigerant fluid will you use?

The type of refrigerant you use depends on the temperatures that your medical chiller will be exposed to. Our systems only use EPA-approved refrigerants as part of our commitment to environmental responsibility.

- - What flow rate is required?

Medical chillers often require a specialized high-pressure pump to ensure fluids flow through the system effectively as the component is operating. If the pump is not sized for the inevitable pressure drops throughout the process, efficiency and performance will be compromised.

- - What is the heat load variation

When medical imaging equipment is scanning, the heat load is at 100% and then drops to 10-20% in between scans. We design our medical chillers to handle that wide load variation with elongated run times, so the compressor doesn’t turn on and off while the component is processing.

- - What is your desired capacity output?

Shifting from a single to a dual circuit medical chiller system can cut capacity output by as much as half. If lowering output is near the top of your priority list, we’ll help you select an efficient medical chiller that will help you get the most uptime.

- - What is your climate?

We design medical chillers for year-round operation in any climate. Understanding your environmental factors such as temperature and humidity can help us engineer the best solution for you.

- - What level of ‘smart’ control features would you like?

Like the intelligence behind smart-home technology, we offer user-friendly micro-processing solutions that allow you to control your medical chiller with the touch of a button – no matter where you are. With this option, you could log in remotely, receive text or email alarm alerts, get virtual tech support, and more.

- - What level of redundancy is required?

Because you measure your effectiveness by uptime, you’ll need a system designed with redundant circuits and other backup systems in mind. Our medical chillers can come with additional redundancy options, such as a city water bypass apparatus, to help keep you up and running.

- - What is your budget?

Finally, considering your budget will help us tailor a solution especially for you. We have a custom-capable standard product line that allows you to choose in-stock quick-ship items or customize an in-stock item with only the bells and whistles you need.

We also offer fully customized solutions for more complex applications. Be sure to let us know about any special requirements you need, including fireproof wire, NEMA 4 electrical protection, preventative alarms, or custom controls programming.

Why choose us for medical chillers

As a high-quality industrial medical chiller manufacturer with over 40 years of experience, choose us as your manufacturing partner because we:

- Have a proven 99.4% uptime rate

- Maintain tight temperature control of +/- 1°F

- Provide robust products and engineered solutions

- Carry the most advanced technology available

- Manufacture in the USA in Bensalem, PA

- Have short lead times – 3-4 weeks

- Carry in-stock systems for quick ships

Related

Discover more related articles

What does a poor control of the relative humidity in the expenses of your...

Trying to maintain the ideal temperature for your industrial processes will be very difficult, if not impossible, if you don’t consider adequate...

Read more »

Why choose a plate heat exchanger for your refrigeration system?

The technology behind the heat exchangers makes them an excellent alternative both in heating systems and industrial refrigeration, replacing coils...

Read more »