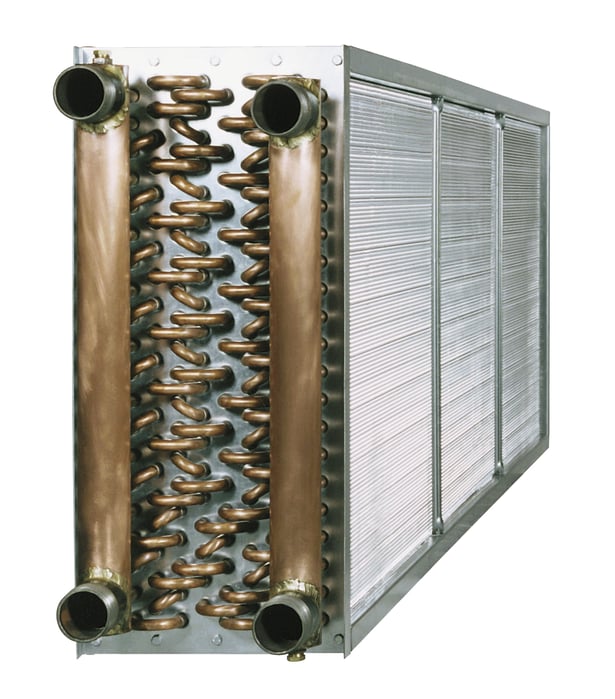

Within the industrial cooling systems, the cooling coils are a component formed by tubes of different materials through which a fluid passes, while these have an external contact with the air or a gas, which allows an exchange of heat.

The fluid that passes through the cooling coils can be composed of water or some refrigerant.

In a cooling system designed for comfort, the cooling coils are components that serve to cool or warm air.

Similarly, the cooling coils are used for the dehumidification of the environment and are part of the equipment whose function is to keep the control of the relative humidity of a cold room or any process that requires specific humidity conditions.

To be more efficient, the cooling coils require flaps that can be of different designs, which fulfill the function of trapping the heat and improving the heat exchange between the fluid that is inside the coil and the ambient air.

The flaps increase the heat exchange surface, and these can also be made of different materials.

The cooling coils separation determines the temperature levels that we want to achieve for the product conservation. The lower the number of cooling coils per inch, the lower the temperature.

Negative temperatures (-) well below the freezing point of water (0 °C) use a greater separation between the cooling coils. Approximately 4 per inch.

On the other hand, temperatures close to 0 °C use less separation. Approximately 6 per inch.

Cooling coils could be used for plants that use hot gas turbine and to eliminate this gas. The installation of the cooling coil equipment could take advantage of the heat emitted for other processes that require this heat for water or other applications.

Most used materials in industrial refrigeration coils

The most commonly used materials for cooling coils and covering flaps in the industrial refrigeration industry are the following:

- Copper tubes and aluminum flaps, the most common in refrigeration.

- Stainless steel tubes and aluminum flaps.

- Galvanized steel tubes and flaps.

- Copper tubes and flaps.

Tubes of copper-nickel, which is a non-ferrous heavy metal, and titanium flaps that support the contact with salt water are used for applications requiring high resistance to corrosion, as is the case of the petrochemical industry.

Industries with greater cooling-coil integration in cooling projects

Many industries require the use of cooling coils as essential components for cooling systems:

- In the hotel industry, for comfort use such as air conditioning or dehumidification processes. In a hotel you can apply up to 600 of these components between the air conditioning of the rooms or the chillers.

- In the healthcare sector for comfort, but also in processes where it is necessary to maintain control of humidity levels due to hygiene issues.

- In the education sector for comfort of classrooms, laboratories or auditoriums.

- In the public sector for government offices.

- In the petrochemical industry where materials such as titanium are used for its manufacture.

- For the use of chillers in cooling systems.

- Etcetera.

These components have a widespread use in the industry and are fundamental for almost all sectors that require cooling in their processes. From an air conditioning equipment to petrochemicals in environments where they require high impact substances, such as sulfuric acid.

Cooling coils in their exterior applications are sensitive to damage from the environment, so proper cleaning and maintenance is essential for the appropriate functioning of the equipment.

As an industrial refrigeration contractor, you can integrate regular maintenance as part of your services by establishing plans that make your client see that a poor state of these components can increase their energy costs or total failure of their systems.

Main manufacturers of cooling coils

Modine

It is a manufacturer of industrial refrigeration equipment and components that has already commemorated its 100th anniversary.

This company, known for its innovation in heat exchange technology, has become a world reference in the design and manufacture of coils for continuous use and for residential, industrial, heating, ventilation and cooling applications.

Froztec International is the brand’s representative in Latin America, which allows us to offer extensive coverage of equipment and technology.

SGS - Krack

With the manufacture of the Krack line equipment, SGS is a leader in the manufacture of cooling technology, including cooling coils for commercial and industrial use.

SGS-Krack’s experience is supported by 80 years of working in the industry.

Direct Coil

It is a company specialized in the design and innovation of technology for heat exchange used in a wide range of applications.

It is characterized by always looking for innovation in the design and efficiency of its components.

At Froztec International, we can support your industrial cooling projects through specialized engineering and calculation, as well as in the choice of the equipment you need to guarantee efficiency and energy use for the systems of your final customers.

Visit our network of advisors in the United States and Latin America. We are prepared to support your quotes to your customers.

Related

Discover more related articles

What kind of cooling equipment does your cooling room need?

Cooling spaces are kept below average room temperature, and so there must be, at all times, a driving force to push the heat inflow from the cooling...

Read more »

Importance of cooling in wine production

The production of wine requires the use and application of cooling systems. These systems must consider the use of energy and the impact they have on...

Read more »