As the head of the purchase department on a SME you shouldn’t have to turn into an expert, or to be an engineer in order to know which equipment you should buy and implement in your refrigeration system: our responsibility is to give you all the information you need to make a good decision.

To know what each piece of equipment does, and what you should be looking for when talking to sellers and consultants about your project, will help you not get a headache from making the wrong choice. That is why knowing exactly what a condensing unit does will be good for your pocket… even when you don’t have to take an engineering exam.

¿What is a condensing unit?

The condenser is one of the most important pieces of equipment in the entire refrigeration system, since it rejects the entirety of the system’s heat: from the heat absorbed by the evaporator, to the heat produced by the energy entrance to the compressor.

It is convenient to place certain ground to fully understand the importance of the process when selecting a condensing unit. In systems that involve heat transfer, a condenser is a device used to condense a substance from its gaseous state to its liquid state.

This appliance is the one that transforms (through condensation) refrigerant gas from its gaseous state to liquid, in order to continue the refrigeration cycle. When doing it, latent heat is abandoned by the substance, and then transferred to the surrounding environment.

Economic impact of the condensing unit

The condensing unit is the great saver of your refrigeration system: by recycling refrigerant gas, it prevents having to consume and spend in this substance each time you want your products cooled.

Condenser variety by application

Condensers can be made according to a number of designs, and they come in many sizes, depending on their application. For instance, a refrigerator uses a condenser to eliminate the heat extracted from the unit’s interior, and send it to the outside.

Condensers are used in air conditioners, in chemical procedures such as distillation, steam power stations and other heat exchanging systems. The use of refrigeration water or surrounding air is common in many condensers, since its disponibility and easy access are optimal for man geographical positions.

What makes a condenser unit

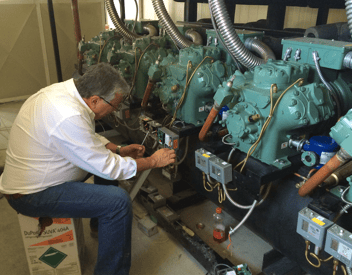

A condenser unit is commonly used in HVACR central systems (heating, ventilation, air conditioning and refrigeration) are generally composed of:

- A heat exchange sector: to cool and condense vapor coming from the liquid refrigerant.

- A compressor: to elevate the refrigerant’s pressure and move it.

- A ventilator: to cool the interior refrigerant by moving the outdoor air through the exchanger.

Where to locate your condenser unit

Some condenser units are located outside the building they are trying to cool off, with tubes that go from the unit to the building: one for incoming refrigerant steam, and another one for the liquid refrigerant coming out of the unit. Of course, a electric power source is needed for the compressor and the ventilator that live inside the unit.

Three condenser unit types

From a basic perspective, there are three main condenser unit types, that divide depending on the mechanism they use to fulfill their duties.

Air-cooled condenser unit

If the condenser is located outside the unit, the air-cooled condenser could be a good choice, facilitating the design’s arrangement. This types of condensers push off the heat to the outside, and are very simple to install.

The most common uses for this condenser are residential air conditioners, meaning that their use is related to comfort. One of the great features of this type of condenser is that they are very easy to clean. As dirt can cause serious problems with the condenser performance, it is strictly recommended to have preventive maintenance.![]()

Water-cooled condenser unit

Even when this type of condenser means a higher investment, they are the most efficient requiring regular maintenance.

It is also common to use assistant systems to disperse the heat, such as cooling towers to keep the water, thermodynamically speaking. To prevent corrosion, water-cooled condenser require a consistent reposition water supply, and a purging system with the water treatment.

Depending on the application, you can choose from an arrange of systems commonly known as chillers, among which the helmet-tube systems stand out. They are all essentially made to produce the same result, but each one in its own way.

Steam-cooled condenser unit

Even though this is the least popular choice, steam cooled condensers can be used either on the inside or the outside of the building, and in normal conditions they work with a low condensation temperature, giving excellent operative advantages.

In general, this are used in big air conditioning commercial units, storage units with a voluminous mass to cool, or a high movement rate.

How to make a quote

This being a strategic choice, the condenser unit should consider the specifics from your project, the type of product you want to cool, your production volume, the space, and the outside temperature and climate and geographical conditions of your plant.

We recommend starting to quote by giving away this information, instead of going for specific equipment first: many times, the gear we think we need are not going to solve our problem.

The case for La Quinta

A very clear example, on Froztec’s experience, is the Hotel La Quinta. What started as a quote for specific equipment evolved until the root of the refrigeration problem was found, and we suggested a whole and profitable solution. You can read the story here.

Related

Discover more related articles

Improving the commercialization of your industrial refrigeration projects...

Competing in the industrial refrigeration world involves several challenges and it is important to be prepared for a market that demands constant...

Read more »

The four big challenges to produce craft beer

As you read this, thousands of people in the world are toasting with a good glass of beer. it’s very likely that just now the memory of this bubbly...

Read more »